- Home

- News & Information

- Order Received for VD4-250GH-OL High-Pressure, High-Flow Hydrogen Compressor for Japan's First Offshore Hydrogen Station

Oct 31,2024

Order Received for VD4-250GH-OL High-Pressure, High-Flow Hydrogen Compressor for Japan's First Offshore Hydrogen Station

MITSUI E&S Co., Ltd. (Headquarters: Chuo-ku, Tokyo, President and CEO: Takeyuki Takahashi; hereinafter "MITSUI E&S") announces that it has received an order from TSUNEISHI CORPORATION (Headquarters: Fukuyama City, Hiroshima Prefecture, President & CEO: Hidetada Kambara) for a VD4-250GH-OL high-pressure, high-flow hydrogen compressor for use in Japan's offshore hydrogen station, which is being built by JPN H2YDRO CO., LTD. (Headquarters: Fukuyama City, Hiroshima Prefecture, Representative Director: Hirotatsu Kambara; hereinafter "JPN H2YDRO").

The goal of the Nippon Foundation Zero Emission Ships Project is to achieve carbon neutrality in the shipping sector amid the global trend toward decarbonization. As part of this project, the VD4-250GH-OL will be used at Japan's first offshore hydrogen station to supply hydrogen to hydrogen-fueled ships, including tugboats equipped with hydrogen co-firing engines. The station is currently being built by JPN H2YDRO.

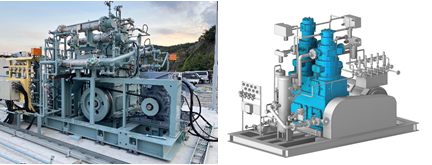

The VD4-250GH-OL's design is optimized for longevity. It enables stable hydrogen compression with minimal downtime and is equipped with technologies based on long track record in high-flow compressors for petroleum refining and chemical plants all over the world by MITSUI E&S and extensive expertise in high-pressure hydrogen compression technology by our group company, KAJI TECHNOLOGY CORPORATION(Headquarters: Sakai City, Osaka, President: Katsunori Matsuoka), who have the largest share market at Japanese hydrogen stations. The VD4-250GH-OL boasts high reliability and durability with the ability to compress hydrogen up to 50 MPa at a flow rate of 100 kg/h.

The compressor is also characterized by its high-pressure high flow rate. Even with this flow rate, it is physically smaller than existing compressors, making it a space-saving compressor that can be used in a wide range of processes for the transportation and supply of hydrogen.

MITSUI E&S began manufacturing reciprocating compressors in 1961 and has delivered more than 1,200 reciprocating compressors to customers all over the world, for use in essential oil refining and chemical plants. MITSUI E&S will continue to contribute to a recycling-oriented and decarbonized society through its supply of compressors to facilities such as hydrogen stations and hydrogen production equipment in the hydrogen market, as well as to SAF plants.

The information contained in the articles is current at the time of publication.

Products, service fees, service content and specifications, contact information, and other details are subject to change without notice.

Contact